The National Reactor Innovation Center (NRIC) has officially opened a cutting-edge research facility designed to accelerate the development of next-generation nuclear technologies.

The new Molten Salt Thermophysical Examination Capability (MSTEC) is located at Idaho National Laboratory (INL). It is all set to begin operations in March and is already being hailed as a milestone for advanced reactor research in the US.

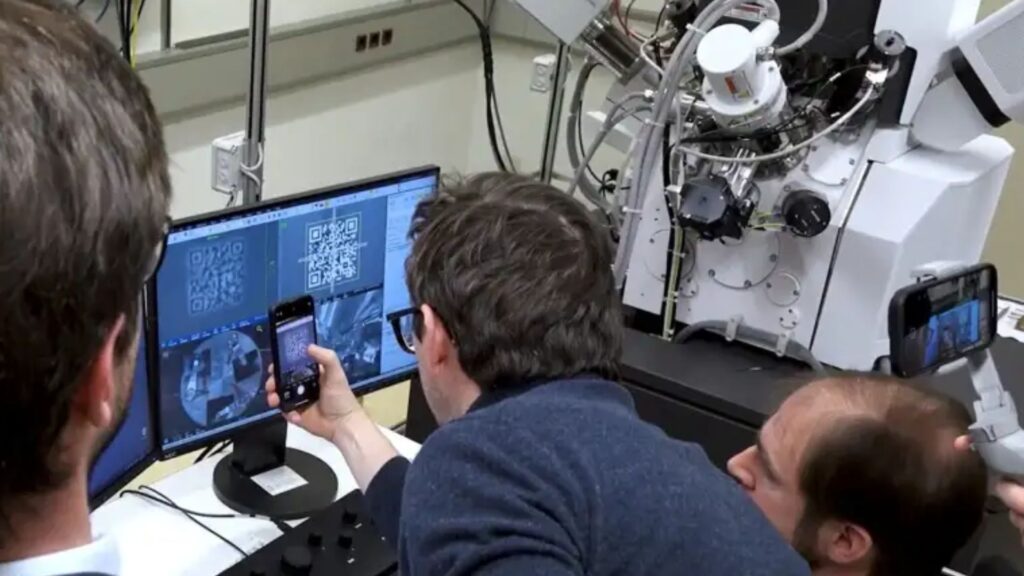

MSTEC engineering and design team, along with the US Department of Energy’s Office of Nuclear Energy and INL officials unveiled the facility.

The facility is expected to play a central role in strengthening America’s research and development of molten salt reactors (MSRs) and in advancing fuel cycle innovation.

READ ALSO: https://modernmechanics24.com/post/cosmic-fireworks-reveal-universe-expand/

A Strategic Boost

MSTEC is a state-of-the-art, shielded argon glove box engineered to handle both irradiated and nonirradiated actinide materials. The facility is specifically designed to examine high-temperature liquids such as molten fuel salts, an essential component of advanced molten salt reactors.

Brad Tomer, director of NRIC, emphasized the broader significance of the new capability. “The establishment of MSTEC marks a major achievement in our quest to advance next-generation nuclear reactor technologies,” Tomer said. “We are providing essential experimental infrastructure and expertise to industry, and MSTEC will help address national energy objectives while propelling the future of nuclear power.”

Several molten salt reactor concepts are currently under development in the US and other nations. While research spans multiple technical areas, understanding fuel salt performance and fuel cycle behavior is important to raising technology readiness levels.

Commercialization and licensing remain uncertain without reliable data on molten salt properties under reactor conditions. MSTEC aims to close that gap.

WATCH ALSO: https://modernmechanics24.com/post/boston-dynamics-atlas-balance-agility/

Among its distinguishing features, MSTEC is expected to be one of the world’s first facilities capable of examining irradiated molten salt materials in a controlled, inert argon atmosphere. This capability is necessary to advance reactor concepts that rely on high-temperature chloride or fluoride salts as fuel, coolant, or both.

The glove box environment allows researchers to work safely with highly sensitive and reactive materials, including plutonium and other minor actinides. It also supports research involving chlorides, fluorides, beryllium, and gases such as hydrogen, chlorine, and fluorine.

Toni Karlsson, INL’s senior molten salt researcher, highlighted the facility’s long-term impact. “MSTEC will significantly advance fuel salt technologies for the Department of Energy, industry, and academia,” Karlsson said. “It also offers a unique platform for training future actinide scientists and fuel cycle researchers.”

MSTEC uses thermophysical and thermochemical characterization equipment, multifunction furnaces, and flexible laboratory space for small-scale experiments. The infrastructure is built to provide reliable, reproducible data for designing, testing, licensing, and operating molten salt reactors.

The facility supports operating temperatures up to 1,000°C for several systems, with certain analytical instruments capable of reaching 1,650°C. Sample volumes are typically small, often less than 10 milliliters. It ensures safe and precise experiments.

READ ALSO: https://modernmechanics24.com/post/gwr-uk-first-battery-passenger-train/

Key Instruments:

Rheometer: A precision device that measures viscosity and fluid flow behavior under varying shear stresses and temperatures. This is crucial for understanding how molten salts move within reactor systems.

Gas Displacement Pycnometer: A nondestructive instrument that measures solid density using argon or helium gas displacement. It operates up to 200°C with accuracy within ±2%.

Densitometer: Based on Archimedes’ principle, this custom-built device measures liquid density and interfaces with a universal furnace for high-temperature molten salt testing.

Universal Furnace: Designed for salt synthesis, electrochemical measurements, probe development, and corrosion studies, the furnace can operate up to 1,000°C and accommodates varied experimental configurations.

Simultaneous Thermal Analyzer (STA): A multifunction instrument that measures weight loss and energy change as a function of temperature, supporting phase diagram development and salt stability research.

Differential Scanning Calorimeter (DSC): Enables high-precision measurements of specific heat capacity and thermal transitions, including melting and crystallization events.

All systems are engineered for remote operation when necessary, enhancing safety while handling radioactive or high-temperature materials.

WATCH ALSO: https://modernmechanics24.com/post/china-sets-maglev-700kmh-record/

Bridging Knowledge Gaps in Molten Salt Behavior

NRIC funded MSTEC to bridge key knowledge gaps in molten salt behavior under reactor conditions. Reliable thermophysical data is essential for predicting material compatibility, corrosion rates, oxide formation, and safe operational limits.

Advanced molten salt reactors promise improved safety, higher operating temperatures, and greater efficiency than traditional light-water reactors. However, achieving regulatory approval and commercial deployment depends on rigorous data collection and material validation.

MSTEC’s integrated approach directly supports design validation and licensing requirements. It allows work to be done by combining experimental infrastructure, technical staff, and analytical tools.

Beyond reactor development, MSTEC also supports fuel cycle research and development. The facility can assist with pyroprocessing of spent nuclear fuel and material accountancy studies related to nuclear safeguards.

Its universal furnace can synthesize novel salt compositions and handle corrosive gases such as nitrogen trifluoride (NF₃) and hydrogen chloride (HCl). Dedicated workspaces allow the integration of new experimental setups, complete with thermocouple, electrical, USB, and fiber-optic feedthroughs.

In complex experimental cases, entirely new equipment can be designed and incorporated within the facility’s flexible layout.

MSTEC’s location within Idaho National Laboratory strengthens its research potential. INL hosts world-class facilities, including the Neutron Radiography Reactor and the Advanced Test Reactor, which provide unparalleled irradiation capabilities. Additionally, Analytical Research Laboratories at INL enable precise isotopic and elemental analysis.

This integration positions MSTEC as a critical hub for molten salt reactor innovation in the US.

By colocating thermophysical testing, irradiation facilities, and analytical capabilities, researchers can conduct comprehensive studies without transferring sensitive materials across multiple institutions. This not only improves efficiency but also enhances safety and regulatory compliance.

READ ALSO: https://modernmechanics24.com/post/ai-helps-kidnapped-robots-find/

Next Generation of Nuclear Experts

While the equipment and infrastructure are advanced, MSTEC’s leadership emphasizes that its scientific workforce is equally important. Engineers, instrument specialists, and molten salt researchers form the backbone of the facility’s capabilities.

The team supports experimental design, troubleshooting, and data interpretation, ensuring complex challenges are addressed with practical solutions.

Karlsson highlighted the facility’s educational dimension. “We are building more than infrastructure,” she said. “We are building expertise and creating opportunities for the next generation of scientists to lead in advanced nuclear technologies.”

As US seeks to expand clean, reliable, and secure energy sources, advanced nuclear technologies are gaining renewed attention. Molten salt reactors offer potential benefits including enhanced passive safety, reduced waste generation, and higher efficiency.

With MSTEC now operational, NRIC strengthens its mission to accelerate advanced reactor demonstration projects and reduce commercialization risks for industry partners.

By delivering high-quality, reproducible data on molten salt behavior, MSTEC provides innovators with the tools needed to design safer reactors, meet licensing requirements, and move closer to deployment.