Chinese scientists developed a 3D printing technology that can create complex millimeter-scale objects in just 0.6 seconds.

The new method sets a global speed record and could transform advanced manufacturing, biomedicine, and micro-technology industries. The research was published online in Nature.

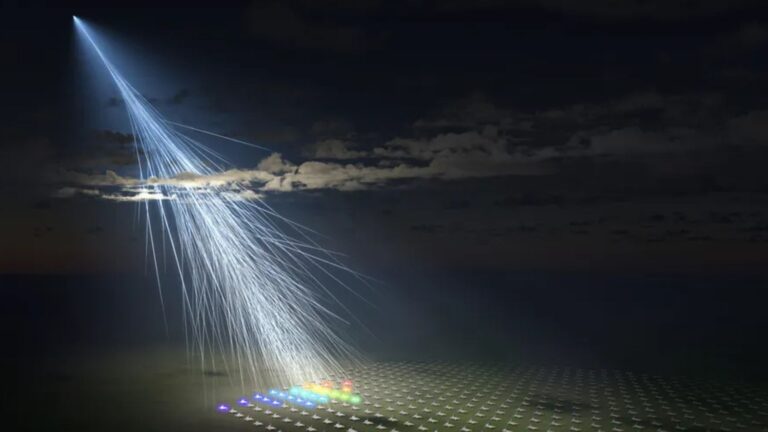

A research team led by Dai Qionghai at Tsinghua University introduced a new high-speed 3D printing system based on holographic light field projection.

The team developed a technique called Digital Incoherent Synthesis of Holographic light fields(DISH). Instead of building objects point by point or layer by layer, the system projects complex three-dimensional light patterns into a material simultaneously.

This design allows entire 3D structures to solidify almost instantly.

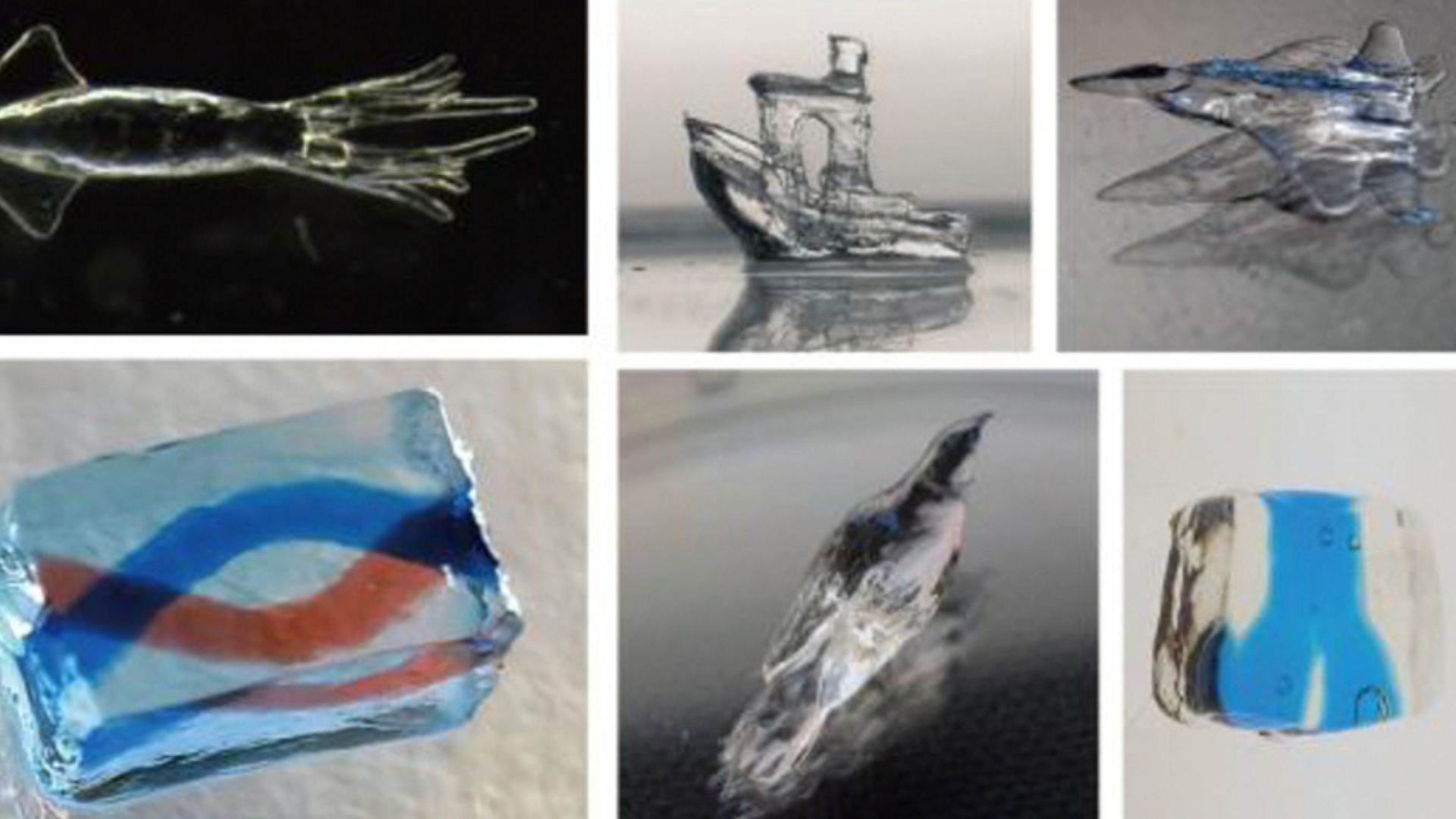

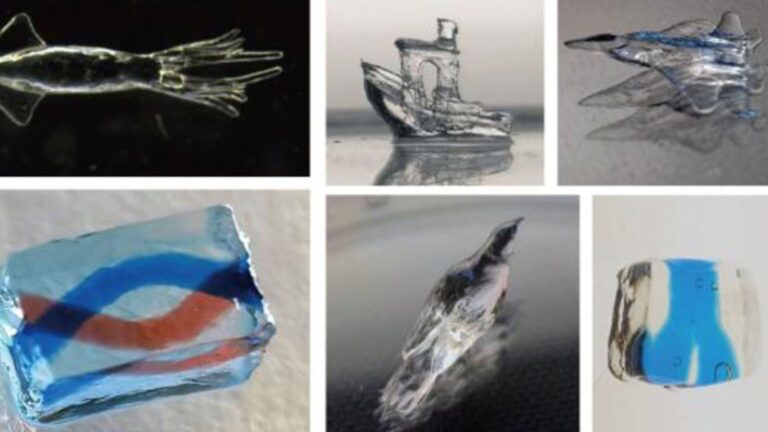

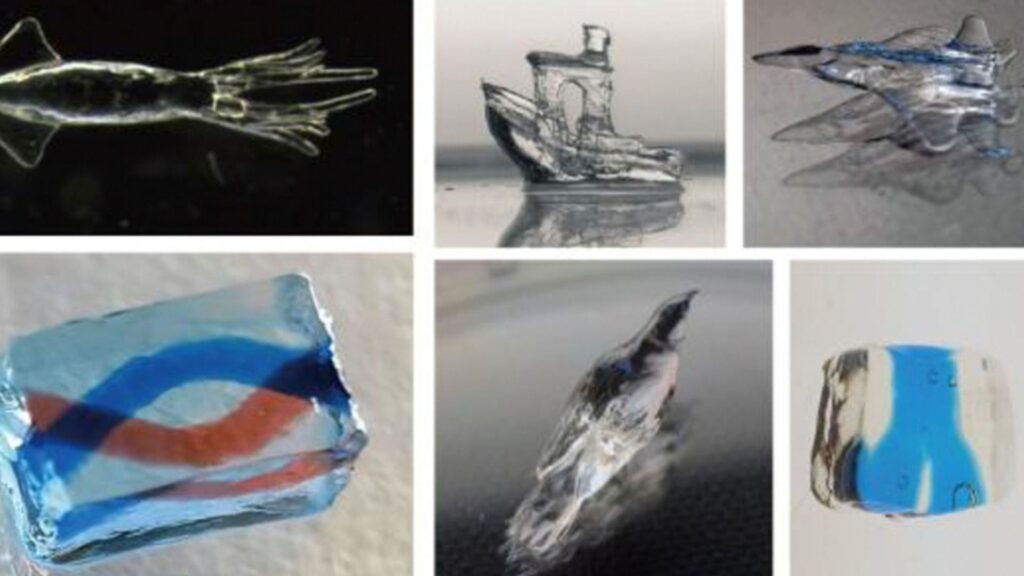

Demonstrations show the printer can fabricate millimeter-scale objects in just 0.6 seconds. The finest feature size reaches 12 micrometers, which is thinner than a human hair. The system achieves a volumetric printing speed of up to 333 cubic millimeters per second.

READ ALSO: https://modernmechanics24.com/post/faw-semi-solid-state-ev-battery/

According to Wu Jiamin, an associate professor and core member of the team, the new optical system removes the need for traditional scanning methods. “Through an innovative optical system design, the digital incoherent synthesis of holographic light fields technology overcomes the speed bottleneck of point-by-point or layer-by-layer scanning printing,” Wu said. “It can accurately project complex 3D light intensity distributions in a short time, enabling rapid 3D object fabrication.”

Speed vs. Precision Problem

3D printing has long faced a major challenge. High precision requires slow mechanical movement. Faster printing often reduces accuracy.

Traditional high-resolution printing of millimeter-scale objects can take tens of minutes or even hours. This limits large-scale production and slows down research experiments.

In addition, many existing systems depend on complex container designs and are affected by the viscosity of printing materials. Precise movement of containers or printing heads is often required, adding mechanical complexity.

The new DISH technology changes this design model. It requires only a single optical plane and does not need precise mechanical movement during printing. This reduces system complexity and increases stability.

WATCH ALSO: https://modernmechanics24.com/post/china-sets-maglev-700kmh-record/

The system works by manipulating high-dimensional holographic light fields. By controlling how light energy is distributed in three dimensions, the researchers can form solid structures directly inside a photosensitive material.

As the printer can rapidly produce intricate shapes with sharp angles and curved surfaces, it is suitable for miniature precision components.

Dai said the technology could be used to mass-produce small parts such as photonic computing components and smartphone camera modules.

The minimal container requirements also expand its use cases. Materials can be placed directly within fluid channels, enabling printing within pipelines or microfluidic systems. This could benefit biomedical engineering and tissue modeling.

Future applications may include flexible electronics, micro-robots, and high-resolution 3D tissue models. By solving the long-standing speed-precision trade-off, the DISH system represents a major leap in additive manufacturing.