Researchers at South Dakota School of Mines & Technology developed an innovative method to extract rare earth elements (REEs) from discarded coal mine waste.

This step could help the United States secure a domestic supply of materials essential to advanced technology, renewable energy, and national defense systems.

The research is led by Venkataramana Gadhamshetty, Ph.D., professor of civil and environmental engineering, and Purushotham Tukkaraja, Ph.D., professor of mining engineering and management. Over the past three years, the team has focused on turning coal mine waste into a valuable resource.

The project began with a seed grant from the National Science Foundation. It later received continued support from the Office of Surface Mining Reclamation and Enforcement and the US Department of the Interior.

“The goal of this study was to develop the technology and understand the process,” Tukkaraja said.

What Are Rare Earth Elements?

Rare earth elements are a group of 17 metallic elements found in the Earth’s crust. Despite their name, they are not always rare. However, they are rarely found in concentrated, easy-to-mine forms.

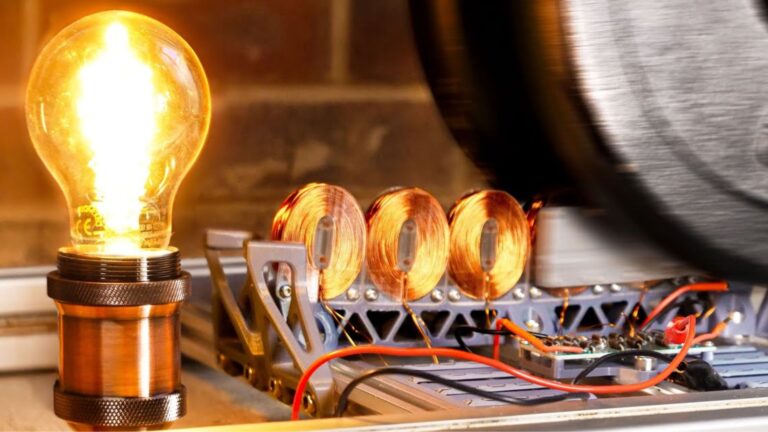

These materials play a vital role in modern life. They are used in electric vehicles, wind turbines, smartphones, LED lighting, fiber-optic communication systems, medical imaging equipment, and defense technologies.

In this study, researchers extracted small quantities of elements such as yttrium, dysprosium, erbium, ytterbium, and gadolinium from coal ash and top rock layers. These are usually discarded during coal mining operations in Wyoming.

“These rare earth elements are essential for technologies such as electric vehicles, wind turbines, smartphones, LED lighting, fiber-optic internet, medical imaging, and national defense systems,” Gadhamshetty said. “Among those elements, dysprosium, ytterbium, and erbium are considered high-value REEs because they are in strong demand and difficult to replace, while yttrium and gadolinium are widely used, high-volume REEs in electronics, lighting and healthcare.”

Why World Needs Rare Earth Materials

The global demand for rare earth materials is rising rapidly. Clean energy technologies depend heavily on them. For example, powerful magnets used in wind turbines and electric vehicle motors require rare-earth elements such as dysprosium and neodymium. Without these materials, many green energy solutions would be less efficient or more expensive.

Rare earth elements are also vital for national defense. They are used in missile guidance systems, radar, advanced communication devices, and military aircraft components. In addition, consumer electronics, including smartphones and laptops, rely on rare earth materials for screens, batteries, and speakers.

Currently, much of the world’s rare earth supply is controlled by a few countries. This creates supply chain risks and economic concerns. Developing a domestic source from coal mine waste could reduce dependency and strengthen national security.

A Three-Stage Sustainable Process

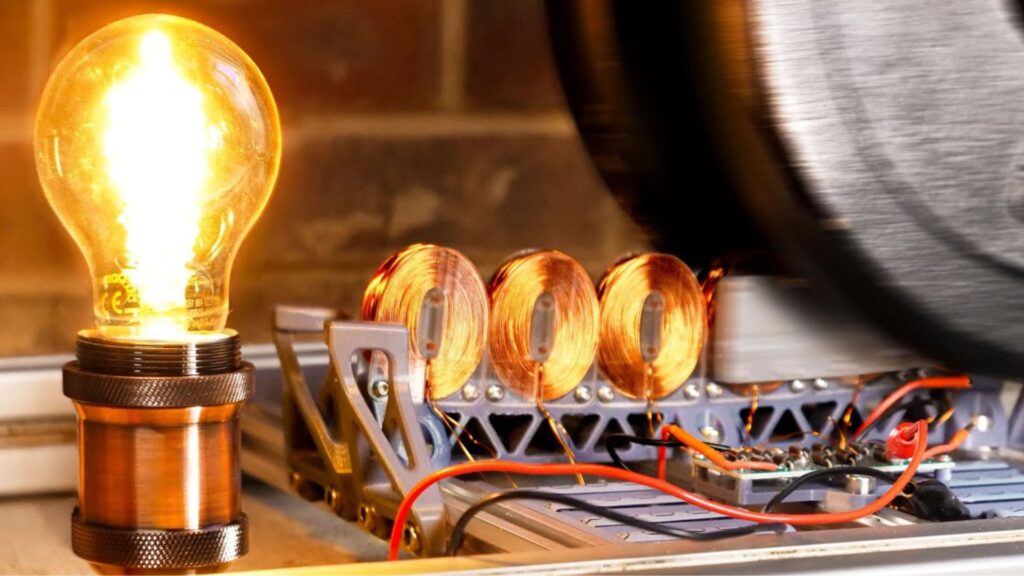

The South Dakota Mines team designed a three-stage treatment process that combines physical, chemical, and biological methods.

In the first stage, researchers break large rock fragments to increase access to the embedded rare-earth elements. This mechanical step improves recovery efficiency.

Next, they use environmentally friendly chemicals to convert the solid rare-earth elements into a liquid. This process allows the team to selectively extract the valuable materials from the waste.

The final stage is biological. Microorganisms absorb dissolved rare-earth elements and concentrate them within their cells.

“Once the transfer is being done, you are able to capture all those precious materials into the microbial cells – using living beings to consolidate the dilute levels of these rare earth elements from larger bodies,” Gadhamshetty said.

He compared the process to human nutrition. “We understand those needs and can optimize conditions, so the microbes naturally take up the rare earth elements, creating a mutually beneficial relationship,” Gadhamshetty said.

This innovative use of microbes makes the process more sustainable and potentially less harmful to the environment compared to traditional mining methods.

Turning Waste Into Opportunity

Coal mining produces large volumes of waste materials, including topsoil layers and coal ash. These byproducts are often stored in landfills or containment areas. This can pose environmental challenges.

By extracting rare earth elements from this waste, researchers address two problems at once. They reduce environmental risks and create a new economic opportunity.

The team has also applied similar principles to treat water from coal mines. By extracting rare earth elements from wastewater, they add further value while improving water quality.

“This work shows how interdisciplinary collaboration can turn an environmental challenge into an economic and strategic opportunity,” Tukkaraja said.

Next Steps Toward Commercialization

While the laboratory results are promising, the next step is scaling up the process. The researchers plan to refine the system, improve efficiency and evaluate its commercial feasibility.

“Once we start incorporating all these different metrics and make it more feasible, we might find stakeholders who would see the value in this solution,” Tukkaraja said.

The research builds on traditional mineral extraction techniques but adds chemical and biological separation methods. The team’s interdisciplinary approach brings together experts in environmental engineering, mining engineering, and metallurgy.

If successfully scaled, this coal waste rare earth extraction technology could strengthen the US rare earth supply chain, support clean energy growth, and reduce environmental impacts from mining operations.

By transforming discarded coal waste into a strategic resource, the South Dakota Mines researchers are showing how innovation can convert an environmental burden into a national asset.