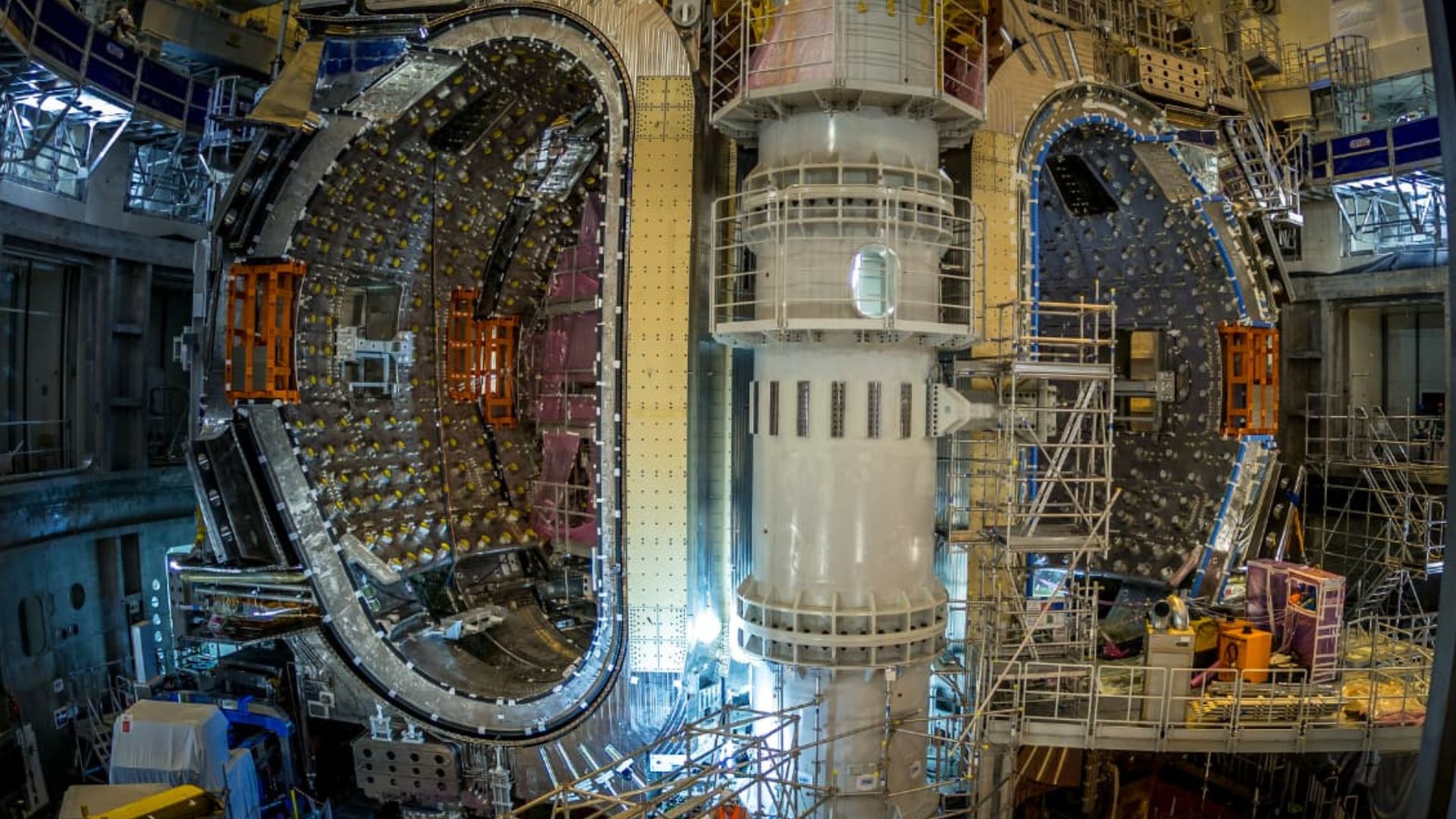

A giant robot is now helping build the International Thermonuclear Experimental Reactor(ITER) in southern France.

The robot, named Godzilla, has a positive mission. It stands about 4 meters tall and can extend its arm up to 5 meters. Engineers call it the most powerful industrial robot ever built for this kind of task. Its job is to prepare for the complex installation of around 20,000 components inside ITER’s vacuum vessel, the heart of the tokamak reactor.

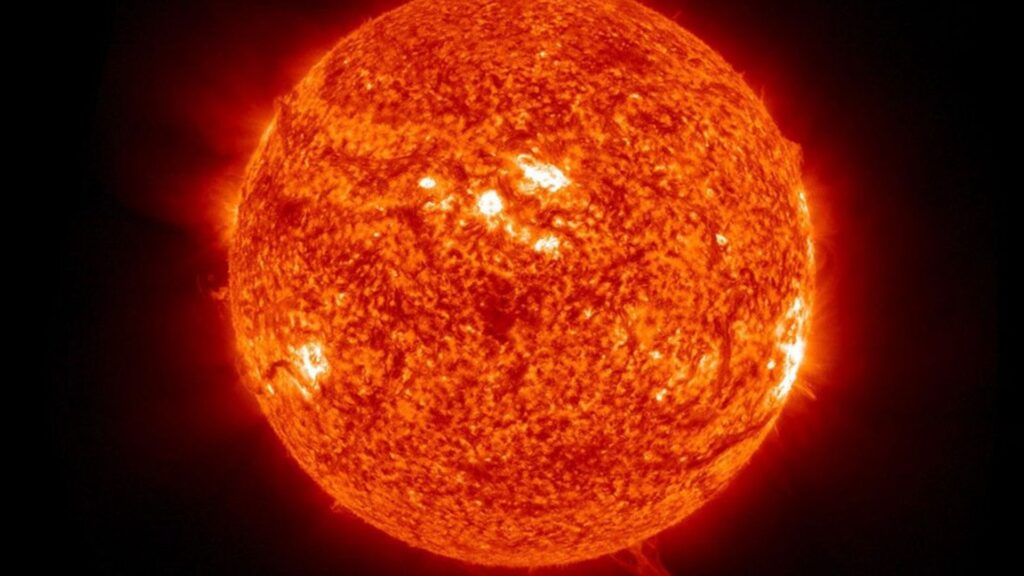

ITER aims to prove that nuclear fusion can become a safe and reliable energy source. The project expects to achieve full magnetic energy by 2036. Deuterium-tritium fusion operations are planned to begin in 2039.

The work inside the vacuum vessel is extremely complicated. Robots will install massive coils, manifolds, and blanket modules that line the inner walls. They will also fit first-wall panels that face the superheated plasma directly. Several layers of systems must be added carefully, one over another.

ITER describes these layers as being ‘superimposed like the skins of a steel onion.’

The assembly will not follow a simple step-by-step sequence. Instead, teams will work in parallel.

READ ALSO: https://modernmechanics24.com/post/sunlight-metal-produce-green-hydrogen/

Robotics expert Raphaël Hery explained, “Specialized teams and assembly tools will move from one part of the vacuum vessel to the next to install a specific ‘layer’ of components.” “As they advance, another team moves in to install the next layer.”

Engineers are using the Godzilla robot to test and refine this approach before real installation begins inside the vessel.

The machine can lift and move loads up to 2.3 metric tons. That strength allows it to handle heavy parts and experiment with different installation tools. One key innovation under testing is a prototype tool changer. This system allows a robot to switch tools quickly and safely during operations.

It is believed that this feature will save valuable time. In total, more than 30 different types of tools will be required during in-vessel assembly. Without an efficient switching system, the process would slow down significantly.

Testing with the Godzilla will begin in March. The team will use mock-ups and interfaces that closely resemble the tokamak environment. Once validated, the tools and methods will be transferred from the engineers to the specialized robots that will perform the actual installation work.

One such machine is an in-vessel tower crane built by French engineering company CNIM Systèmes Industriels. Engineers will adapt and optimize it based on lessons learned from the Godzilla trials.

Another key machine is the blanket assembly transporter. ITER describes it as a monster three times the size of Godzilla. The transporter is currently in detailed design and will be manufactured by Indian engineering giant Larsen & Toubro.

WATCH ALOS: https://modernmechanics24.com/post/chinese-company-new-humanlike-robot/

While robotics development moves forward, construction of the tokamak itself continues steadily. On January 28–29, workers successfully installed sector module 8, which weighs about 1,300 metric tons. It became the fourth of nine sector modules lowered into the tokamak pit. Four more sector installations are scheduled for 2026.

With massive components, international cooperation, and advanced robotics working together, ITER is entering a crucial phase. The Godzilla robot is definitely helping lay the groundwork for a future powered by fusion energy.