UK-based startup Space Forge has successfully generated plasma at a blistering 1,832 degrees Fahrenheit (1,000 degrees Celsius) aboard its ForgeStar-1 satellite, marking the world’s first operation of a commercial semiconductor manufacturing tool in space. This critical milestone paves the way for producing novel, ultra-efficient semiconductor materials in the unique environment of microgravity—a feat previously confined to the International Space Station.

Imagine a miniature, self-contained factory orbiting Earth, forging the advanced materials that will power the next generation of electronics. That vision took a giant leap toward reality when the microwave oven-sized ForgeStar-1 satellite, launched in June 2025, powered up its core furnace for the first time. By creating the intensely hot, ionized gas state of plasma in orbit, Space Forge has proven it can replicate the extreme conditions needed for high-quality crystal growth—the foundational step in making semiconductors—autonomously in space.

“This achievement establishes ForgeStar-1 as the first free-flying commercial semiconductor manufacturing tool ever operated in space,” the company announced. For Joshua Western, CEO and co-founder of Space Forge, this is a transformative moment. “Generating plasma on orbit represents a fundamental shift,” Western stated. “It proves that the essential environment for advanced crystal growth can be achieved on a dedicated, commercial satellite—opening the door to a completely new manufacturing frontier.”

READ ALSO: https://modernmechanics24.com/post/china-solid-state-ev-batteries-major-step/

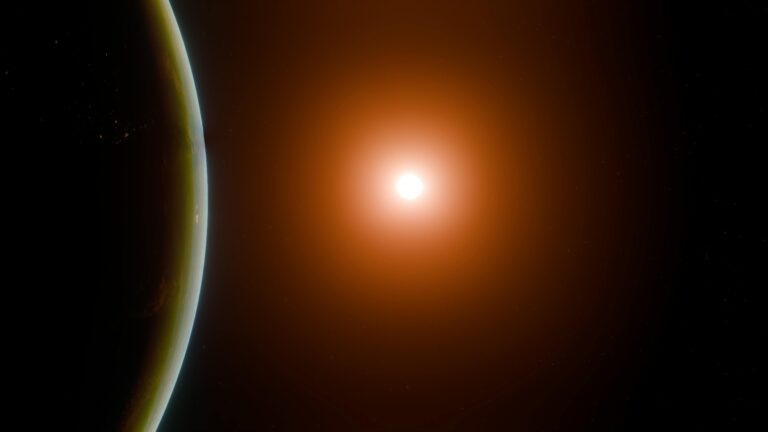

Why go through the immense trouble and cost of manufacturing in space? The answer lies in gravity—or the lack of it. On Earth, gravity causes convection currents and sedimentation during the crystal growth process, leading to impurities and defects in the atomic structure of semiconductors. In the weightlessness of orbit, atoms can align with near-perfect order. The result, according to Space Forge, could be semiconductor materials with performance so superior that they enable reductions in the energy consumption of electronic devices by a staggering up to 60 percent.

The company’s ambitious roadmap involves using rare materials like gallium nitride and silicon carbide to forge these space-made semiconductors. These materials are crucial for future 6G telecommunications, powerful electric vehicles, and next-generation computing, where efficiency and heat tolerance are paramount. While ForgeStar-1 is purely a testbed that will deorbit later this year, its data is the blueprint for the real prize: the ForgeStar-2 mission.

WATCH ALSO: https://modernmechanics24.com/post/isro-gaganyaan-crew-parachute-validation/

Fueled by a substantial Series A funding round of £22.6 million ($30.5 million) raised last year, Space Forge is already building its successor satellite. ForgeStar-2 will be equipped with a novel, reusable heat shield designed to survive the fiery plunge through Earth’s atmosphere and deliver its batches of pristine, space-forged semiconductors safely to the ground. This would transition the company from demonstrating capability to conducting genuine, valuable in-orbit production.

The successful plasma ignition is more than a technical checkmark; it validates an entire new economic sector. By moving from the shared, busy environment of the ISS to a dedicated commercial platform, Space Forge is demonstrating that scalable, autonomous manufacturing in space is viable. It’s a bold bet that the unparalleled quality of materials produced in microgravity will justify the mission cost, creating a high-tech supply chain that begins in low Earth orbit. The factory of the future, it seems, may have no floor at all.

READ ALSO: https://modernmechanics24.com/post/mars-surface-electrical-dust-storms/