A research team at Japan’s RIKEN Center for Emergent Matter Science has engineered a new type of plastic from abundant plant cellulose that is strong, flexible, and completely degrades in seawater within hours—without leaving behind any harmful microplastics. The breakthrough, led by Professor Takuzo Aida, could offer a practical solution to global plastic pollution.

The quest for a truly sustainable plastic—one that performs like conventional plastic but vanishes safely in the environment—has taken a major leap forward. Scientists at Japan’s premier research institute, the RIKEN Center for Emergent Matter Science (CEMS), have developed a plant-based material that not only matches the strength of petroleum plastics but also dissolves completely in saltwater, leaving no trace. Led by Professor Takuzo Aida, the team’s work, published in the Journal of the American Chemical Society, addresses the critical flaw in most “biodegradable” plastics: their failure to degrade in marine environments.

The innovation builds on previous research where the team created a supramolecular plastic that broke apart in seawater. That version, however, wasn’t ideal for mass production. The new material, dubbed CMCSP (Carboxymethyl Cellulose Supramolecular Plastic), solves this by using a commercially available, FDA-approved wood-pulp derivative called carboxymethyl cellulose. This is mixed with a safe, positively charged crosslinking agent. When combined in water, they form a strong network held together by salt bridges—bonds that naturally break in the presence of seawater.

READ ALSO: https://modernmechanics24.com/post/army-first-battery-locomotive-fort-hood/

But there was a catch. The initial cellulose-based plastic was too brittle. “What the team needed was a good plasticizer,” explains the study. After extensive testing, they found the perfect ingredient: choline chloride, another FDA-approved food additive. By adjusting the amount of choline chloride, the researchers could fine-tune the plastic’s properties, creating a material that could range from glass-like hardness to an elastic form stretchable up to 130% of its original length. It can also be made into thin films as slim as 0.07 mm.

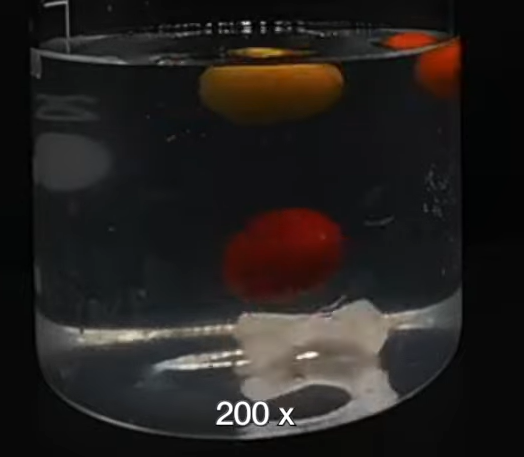

The performance is striking. A video shows a bag made from the material rapidly decomposing in seawater. Unlike plastics that fragment into microplastics over years, this plastic’s molecular network fully disintegrates. “This technology will help protect the Earth from plastic pollution,” stated Professor Takuzo Aida. He emphasized the practical leap from their earlier conceptual work: “This study shows that our work is now at a more practical stage.”

The material’s practicality is key. Its components are inexpensive, widely available, and already cleared for use. “Nature produces about one trillion tons of cellulose every year,” Aida noted, highlighting the scalability of using this abundant natural polymer. The plastic retains desirable qualities like transparency and processability while being fully recyclable in a closed-loop system.

READ ALSO: https://modernmechanics24.com/post/shaking-magnetization-quantum-future/

This breakthrough arrives amid a growing microplastics crisis, with contaminants found from the deepest ocean trenches to human blood. By creating a plastic that performs its duty and then cleanly exits the environment, the RIKEN team has provided a compelling blueprint for a future where plastic pollution could be a problem of the past, not a legacy for the future.