Engineer Matt Denton turned a standard Prusament filament roll into a fully functional remote-controlled robot called SpoolBot.

At first sight, SpoolBot looks exactly like a typical 2kg Prusament spool used in many 3D printers.

The orange filament is wrapped around the drum in a realistic pattern. But this spool can roll across the floor on its own, surprising anyone who sees it move.

The project began when Prusa Research, the company behind Prusament filament, sought a creative, one-of-a-kind gift. They approached Matt Denton to transform a genuine spool of filament into something extraordinary while preserving its outer appearance.

READ ALSO: https://modernmechanics24.com/post/anduril-launch-drone-contest-jobs-prize/

Denton started from scratch using a real spool. He preserved the authentic look so that it would remain almost impossible to tell it was a robot.

“I kept the outward appearance the same,” Denton explained in his build notes. The spool still appears to be a normal filament roll sitting quietly until it begins to move.

How the Hidden Robot Works

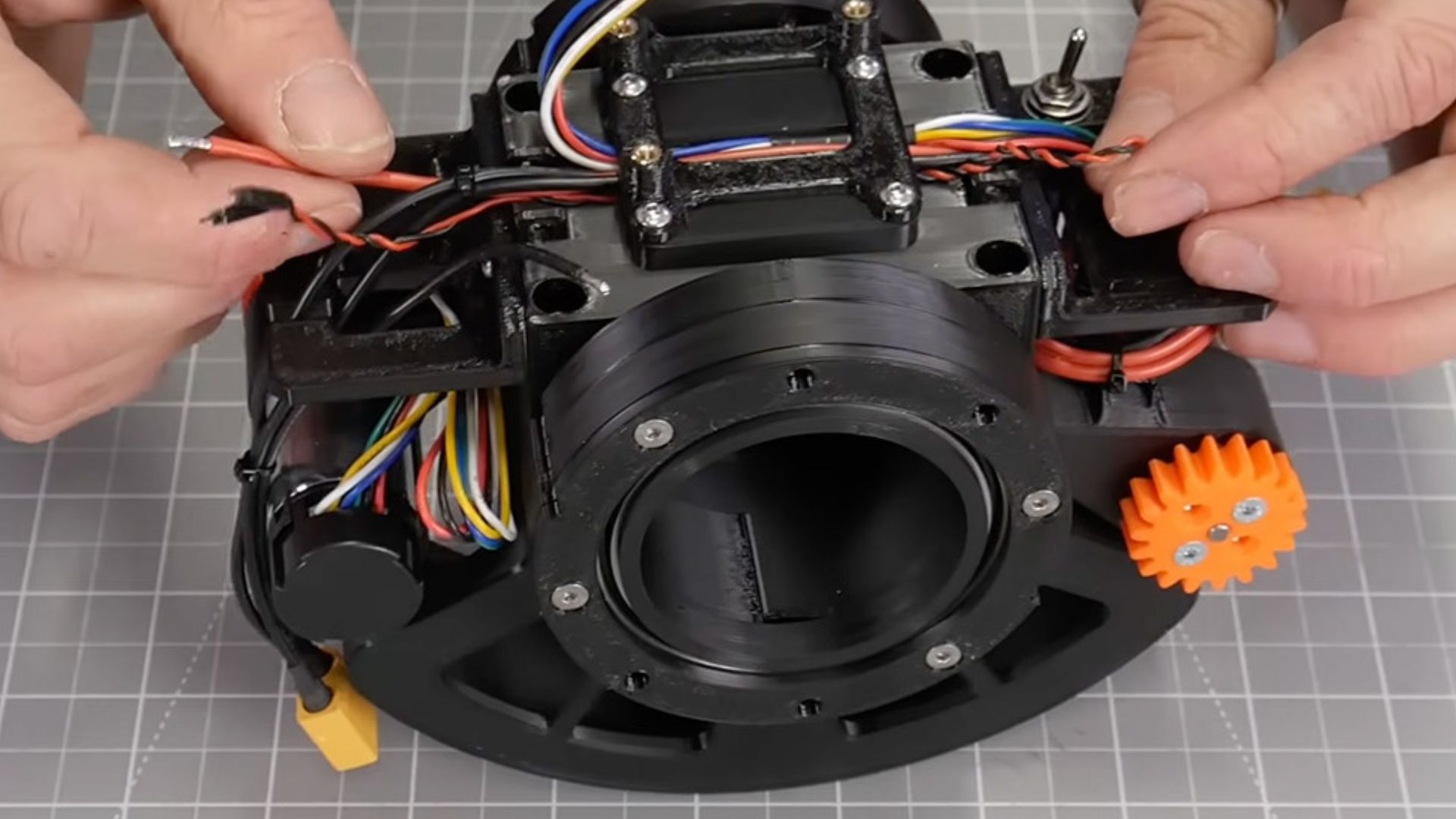

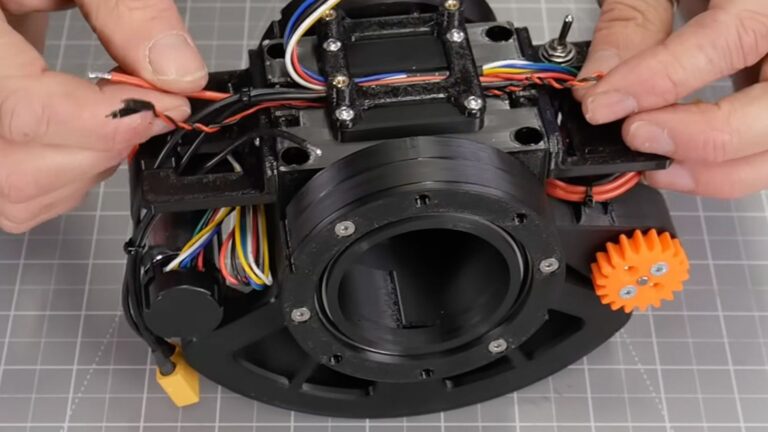

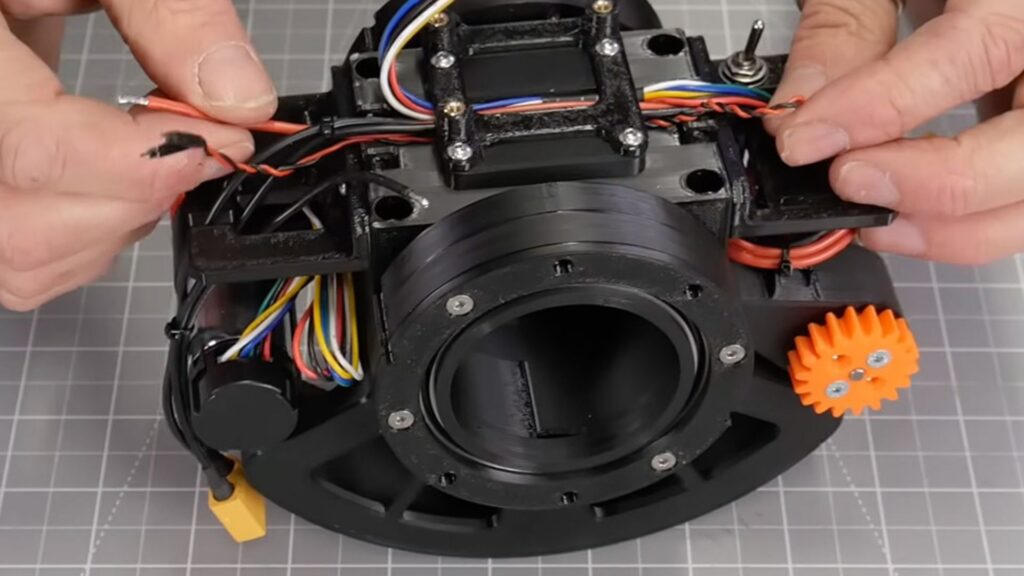

Inside the spool, Denton installed an internal frame to securely hold everything. One side of the spool is fixed, while the other is attached with magnets so he can access the electronics. The black plastic edges of the spool act as driving wheels.

SpoolBot runs on two geared DC motors from Pololu. Each motor includes an encoder that tracks movement and speed. A DFRobot Romeo Mini ESP32-C3 board controls the system. It works together with a BNO085 IMU sensor to monitor balance and stability.

The batteries are placed low inside the spool. This design keeps the robot upright by acting as a counterweight. The system uses differential drive technology. When both motors spin at the same speed, the spool rolls straight. When speeds vary, the spool turns smoothly.

The IMU constantly checks movement. If the spool becomes unstable, the system slows the motors to prevent tipping. Gyro feedback also helps it stay balanced on uneven surfaces, such as carpets.

WATCH ALSO: https://modernmechanics24.com/post/china-launches-80000-ton-fujian-aircraft-carrier/

SpoolBot offers several operating modes. It can remain in one spot, return to its starting point, cruise at a set speed, or spin at full or half speed. The outer shell rotates freely on the center hub because of the installed bearings.

Denton used 3D-printed parts made from black PETG and orange PLA. Heat-set inserts and precision bolts hold the components firmly in place. He completed the entire project in about five weeks, including CAD design, printing, assembly, and coding.

Why This 3D Printing Robot Matters

SpoolBot shows how creative engineering can push the limits of 3D printing and robotics. It highlights the flexibility of modern microcontrollers, sensors, and 3D-printed components.

Denton has shared the build files and source code on Printables and GitHub. He even released a video guide to help others recreate the project.

READ ALSO: https://modernmechanics24.com/post/machine-eye-beats-human-vision-speed/

By turning a simple filament spool into a smart robot, Denton proves that innovation often begins with everyday objects. SpoolBot shows how 3D printing, robotics, and open-source collaboration continue to inspire makers worldwide.