A robotic hand that moves with human-like precision is helping researchers crack one of robotics’ toughest challenges. London-based Shadow Robot Company has built a hand with 40 metal tendons that can manipulate objects smoothly, giving developers a tool to teach robots how to grip, turn, and handle items just like people do. Around 200 of these hands are now being used by universities and tech firms worldwide.

The problem is simple: Almost everything in our world is designed for human hands. Doorknobs, tools, cups, and boxes all expect fingers that bend, grip, and feel. But building a robot hand that can do all that has frustrated engineers for decades.

Rich Walker, director at Shadow Robot, has been working on this since the 1990s. His first hand was made from wood, springs, and rubber bands. “A lot of it was done with just stuff that we had,” he remembers.

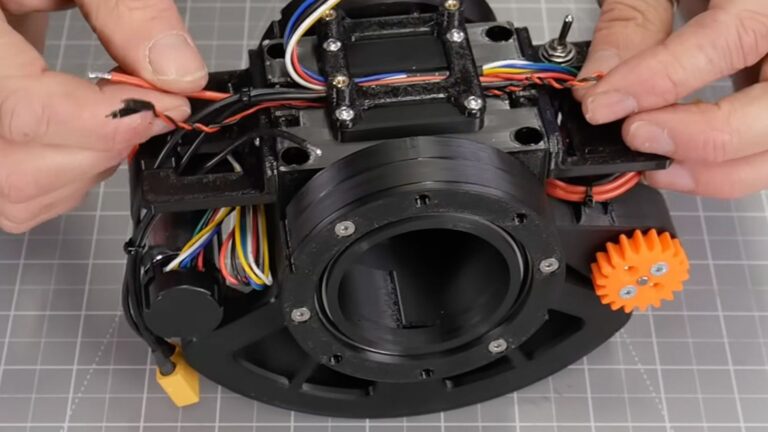

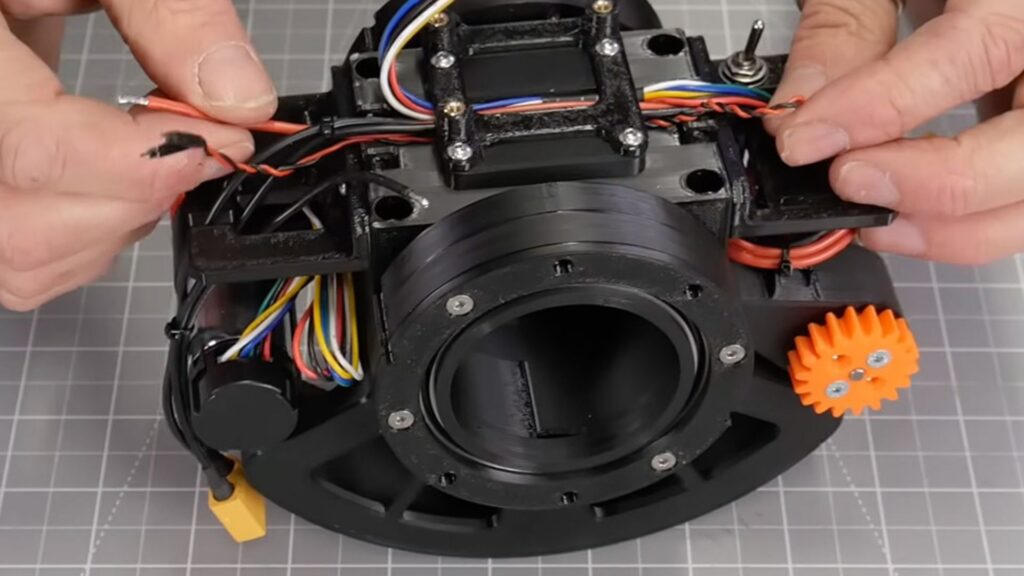

Today’s version looks nothing like that prototype. Inside cylindrical forearms, small electric motors called actuators pull on metal tendons. These tendons move each finger with surprising smoothness.

READ ALSO: https://modernmechanics24.com/post/spain-stealth-drone-world-defense-show/

When a beginner tries the hand for the first time, the movements feel natural. Sensors strapped to the fingers send signals, and the robotic hand copies the actions. There is no flailing or knocking things over. Just precise, controlled motion.

But this hand is not meant for factory floors yet. It is a research tool. Walker calls it “a development kit for dexterity.” Researchers use it to explore what robots can do. Then they take those lessons to build larger systems or cheaper hands for real-world use.

The challenge is massive. Bren Pierce, founder of Bristol-based robotics startup Kinisi, puts it plainly: “I think the hand is the hardest, most complex part of any humanoid robot.”

His company runs trials with ten KR1 robots in commercial spaces. Right now, these robots use different grippers for different jobs. Strong pincers lift heavy boxes. Suction devices handle delicate items.

Pierce wants one hand that can do everything. “Everyone has been dreaming for 40 years of one robot hand to rule the world,” he says. His team built a three-fingered prototype that works well. But making it durable, scalable, and affordable is another story.

WATCH ALSO: https://modernmechanics24.com/post/us-supersonic-jet-cuts-flight-time-silences-sonic-boom/

Cost is a huge barrier. Kinisi’s prototype hand cost about £4,000 ($5,400) to build. That is ten times more than the simple pincer they currently use, which costs just £400.

Even Elon Musk admits this is hard. At a summit in Los Angeles last year, he said building a robot hand is one of the three toughest problems in humanoid robotics. The others are creating AI that understands the world and manufacturing robots at scale.

Musk promised Tesla’s new Optimus robot will have “the manual dexterity of a human.” But experts are skeptical.

Nathan Lepora, Professor of Robotics and AI at Bristol University, has studied robot hands his entire career. He calls Musk’s promise “rubbish.” Human-level dexterity is still years away. “It won’t happen in two years, but we might be talking about 10 years for this to happen,” Lepora says.

Lepora works on tendon-driven hands similar to Shadow Robot’s design. He believes this approach will eventually lead to cheaper, better hands. But he also sees progress elsewhere.

Chinese companies are trying a different method. Instead of tendons, they place small motors directly inside the fingers and joints. Wuji Technology, based in Shanghai, builds hands this way. Each finger has four independently controlled joints, allowing very detailed movements.

Yunzhe Pan, co-founder of Wuji, says their hand is durable and will only get stronger. But it comes at a price: $12,000 (£8,800) per hand. Pan promises they will bring the cost down over time.

READ ALSO: https://modernmechanics24.com/post/china-wing-loong-x-drone-eyes-global/

Wuji’s hand also includes piezoelectric sensors. These convert pressure into electrical charge, giving the robot a sense of touch. That could be a game-changer. Robots that feel what they hold can handle objects more carefully.

But touch sensors have their own problems. Pierce points out that many research sensors work great for six months, then fail. In industry, robots need to run for ten years without breaking.

Still, there is reason for hope. Lepora says tactile sensing always felt like a technology that was ten years away. But the billions of dollars now pouring into humanoid robots are speeding things up. “Things are changing,” he says.