Italy completed its first certified 3D-printed house, taking a major step toward sustainable living.

Itaca, the innovative structure, was built by Italian company WASP at its Shamballa open-air laboratory in the hills of Northern Italy.

The project showcases how advanced technology, natural materials, and circular economy principles can come together to create an eco-friendly, self-sufficient home.

WASP said the project aims to redefine how homes are built in the future. “With Itaca, we want to prove that 3D-printed buildings can meet the same safety and quality standards as traditional houses, while dramatically reducing environmental impact,” the company stated.

First Certified 3D-printed House in Italy

Itaca is the first 3D-printed house in Italy to receive official certification. This is significant because Italy has some of the strictest construction regulations in Europe, particularly given its high earthquake risk. Meeting these standards means the building model can be replicated in many other countries with similar or less demanding regulations.

READ ALSO: https://modernmechanics24.com/post/3dprinted-soft-robots-programmable-shape/

The house was built by WASP 3D Build, a startup created by WASP to focus on large-scale 3D-printed construction. The project is part of a broader vision to develop a self-sufficient farm and living system based on a circular micro-economy, where waste is reused, and local resources are maximized.

According to WASP, “Italy is one of the most complex environments for construction approval. Achieving certification here shows that this model can work almost anywhere in the world.”

Robotic Arms Construction

The construction of Itaca used an advanced version of the Crane WASP 3D-printing system. Four robotic arms were placed at the corners of a hexagonal layout, enabling them to print different wall sections simultaneously. This setup helped in reducing construction time.

“When all four arms work together, they can complete the structural shell of a house in just a couple of days,” WASP explained.

Each wall of the house took about 24 hours to print. The final structure covers an area of 164.9 square metres, with walls standing 3.8 metres high.

WATCH ALSO: https://modernmechanics24.com/post/china-astronauts-mice-space-research-mission/

Nature-Inspired Design

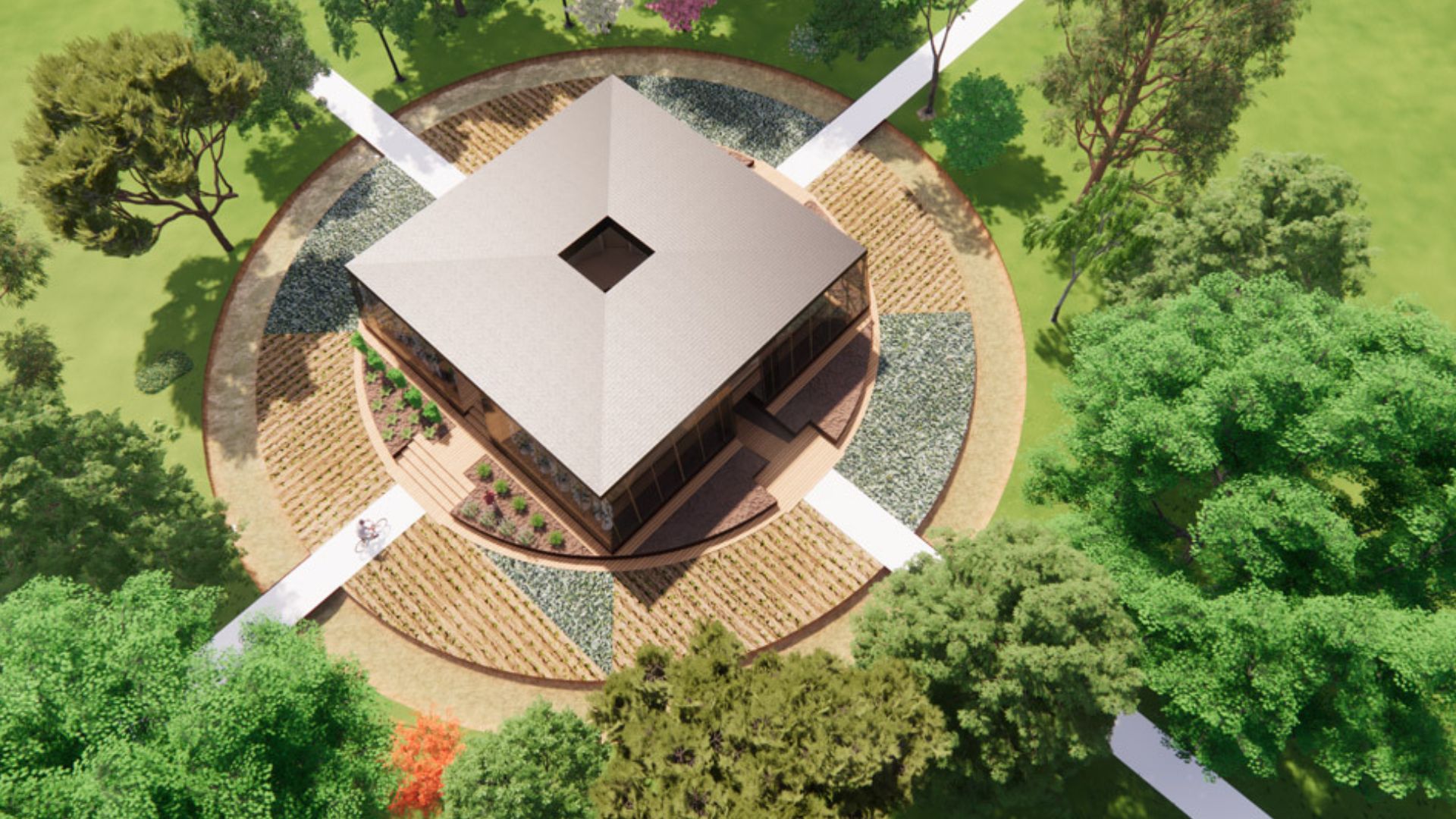

The design of Itaca draws inspiration from a Mandala, a geometric form often associated with balance and harmony. The layout consists of a square enclosed within a circle, with four main walls positioned at the corners. Each wall features a central opening, creating a balanced, open living space.

Beyond aesthetics, the geometry supports structural strength and efficient use of materials.

Building with Low-Carbon Materials

One of Itaca’s most important features is its use of a lime-based mixture instead of concrete. Traditional cement is one of the largest sources of carbon emissions in the construction industry. By avoiding concrete, WASP significantly reduced the building’s carbon footprint.

The company said, “We chose lime because it has lower emissions, high durability, and excellent breathability.” This breathability helps regulate indoor temperature naturally and prevents mold growth.

To improve strength and comply with earthquake regulations, reinforcement columns will be installed within the walls. These also support the green roof that will be installed on top of the building.

Balancing Negative CO₂ Emissions

The walls of Itaca are significantly thick, measuring 60 to 70 centimetres. Inside these walls, WASP used insulation made from rice husks, a waste product from the agri-food industry, mixed with natural lime powder. This creates internal insulation that improves energy efficiency without adding synthetic materials.

By combining natural materials with industrial by-products, WASP said the walls achieve a negative CO₂ emissions balance. That means they absorb more carbon than they produce during construction.

In regions with flexible regulations, the same design can also be built using earth as a construction material, further lowering environmental impact.

READ ALSO: https://modernmechanics24.com/post/dlr-rotor-blade-helicopter-noise-reduction/

Self-sufficient Home

Itaca is more than just a house. It is part of a broader experiment in self-sufficient living. The project includes systems to manage food, water, and energy within a limited space.

Two rainwater collection basins have been built around the house to store water, prevent soil erosion, and support farming. A green roof will improve insulation and encourage biodiversity, while solar panels will help meet the home’s energy needs.

WASP said, “Our goal is to show that four people can live independently within a space of just 33 metres in diameter, without harming the environment.”

The walls also include built-in radiant heating systems and electrical wiring, all embedded during printing. This eliminates the need for additional construction work later and reduces material waste.

A Living Research Model

Itaca is designed as a collective research and development project. All construction methods, materials, and solutions used in the house are digitised and shared, allowing others to replicate or improve upon them.

“The digitisation of knowledge and digital manufacturing guide this project,” WASP said. “We want Itaca to be a widely accepted model, not a closed experiment.”

By combining technology, sustainability, and open collaboration, Itaca offers a glimpse of a future where homes are built faster, maintained more cheaply, and are far kinder to the planet.